If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

![]() Whatsapp : +8613589078962

Whatsapp : +8613589078962

![]() Email : [email protected]

Email : [email protected]

| Section Shape | ROUND |

|---|---|

| Surface Treatment | Hot Rolled |

| Tolerance | ±1% |

| Oiled or Non-oiled | Non-oiled |

| Invoicing | by theoretical weight |

| Place of Origin | China |

| Alloy Or Not | Non-Alloy |

| Standard | JIS ASTM AiSi EN |

| Grade | Q195/Q235/Q345 |

| Delivery Time | 15-21 days |

| Application | Fluid Pipe, Boiler Pipe, Drill Pipe, Hydraulic Pipe, Gas Pipe, OIL PIPE, Chemical Fertilizer Pipe, Structure Pipe |

| Special Pipe | Other, Thick Wall Pipe |

| Length | 6m |

| Certificate | API, ce, Bsi, JIS, ISO9001 |

| Processing Service | Welding, Punching, Cutting, Bending, Decoiling |

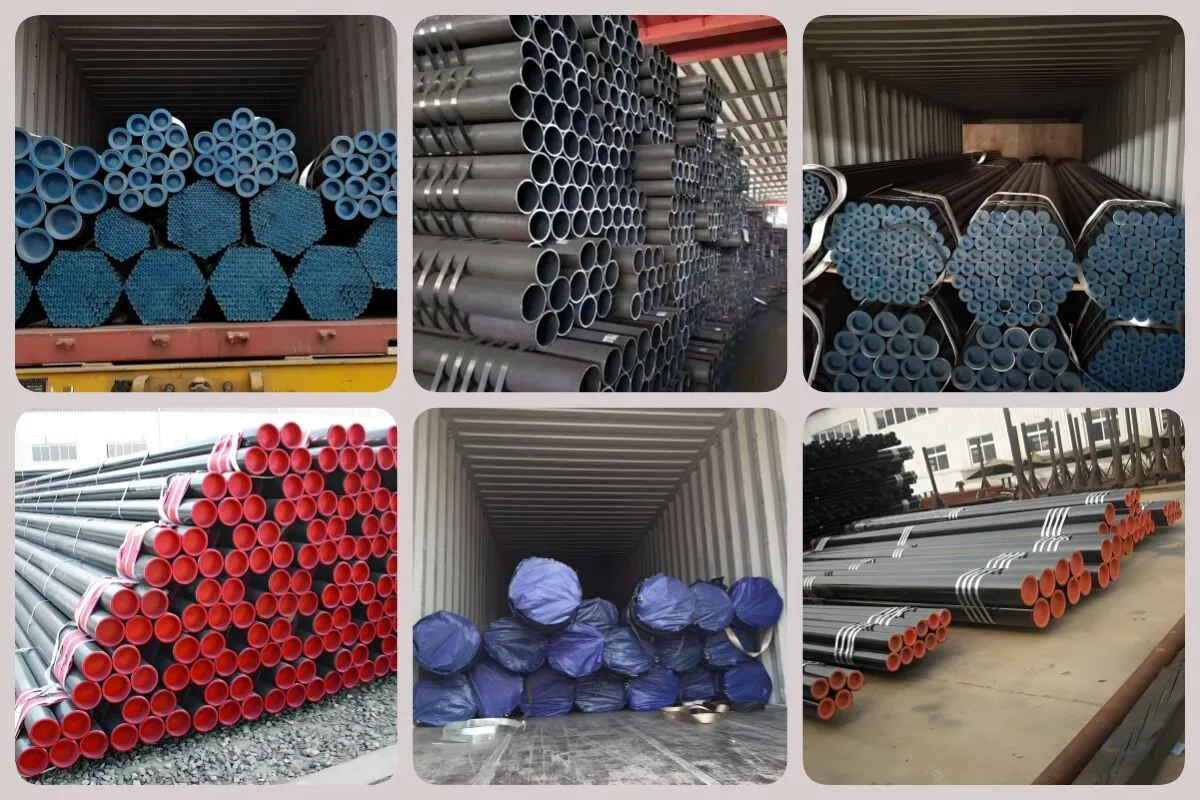

| Product name | Carbon Steel Pipe |

| Type | Seamless Round Steel Pipe |

| Surface | Customers’t Requirement |

| Usage | Fluid Used |

| Material | 10#.20# 45# 16Mn |

| MOQ | 1 Ton |

| Technology | Seamless Hot Rolled |

| Sample | Avaliable |

| Wall Thickness | 6mm-70mm |

| Payment | TT DP LC |

Carbon steel pipes are usually hollow cylinders with a silver-gray or black surface color. The outer surface may exhibit different roughness due to different processing techniques, such as the surface of the cold-drawn pipe is relatively smooth, while the surface of the hot-rolled pipe is slightly rough.

Since the main components are iron and carbon, the density is relatively high, about 7.85g/cm ³, which makes the carbon steel pipe heavier and has a certain texture and stability.

It has high strength and can withstand greater pressure and tension. Its hardness is also higher, depending on the carbon content and heat treatment method. For example, steel pipes made of high-carbon steel have higher hardness and are suitable for applications that require wear resistance and deformation resistance.

It has good toughness and will not break easily when subjected to a certain degree of impact. At the same time, it also has a certain degree of ductility, which can be changed by bending, flailing and other processing methods, but the ductility is worse than that of some non-ferrous metal pipes.

It is a good thermal and electrical conductor, but its thermal and electrical conductivity is slightly inferior to that of metals such as copper. It can play a role in some simple application scenarios that require heat transfer or electrical conductivity.

The melting point is high, between 1370 and 1530 degrees Celsius. The thermal expansion coefficient is relatively small, and the dimensional change is relatively stable when the temperature changes, which is more favorable for some piping systems with higher accuracy requirements.

Carbon steel pipes can be replaced with some metal salt solutions. This reaction is of great significance in some chemical industrial processes or in the study of pipeline corrosion mechanisms.

It has been selected as one of the top 500 Chinese enterprises for 14 consecutive years, with strong financial and technical strength.

Process efficiencyDRP information is fully integrated and controlled, and the steel production process is at a high level.

A steel enterprise that takes steel production as its leading industry and integrates commercial, high-tech and other industries.

Created a number of "firsts" in China's steel industry, with strong R & D capabilities and technological innovation capabilities

The products cover products, varieties, and specifications, and can meet the diverse needs of customers in different fields.

Products with high quality quickly occupied the domestic market and were successfully exported to many countries and regions.

Our factory manufactures a comprehensive array of steel products, including but not limited to, structural beams, steel bars, plates, and coils. We also offer bespoke solutions catering to specific dimensions and compositions as per customer requirements.

Absolutely, all our steel products adhere to international standards and undergo rigorous quality assurance tests. We hold various certifications, including ISO 9001, emphasizing our commitment to quality. Each product batch comes with a certification detailing its grade and compliance standards.

Yes, we are equipped to manage significant order volumes even within constrained timelines, thanks to our advanced operational processes, sizable workforce, and efficient logistics network. However, we always suggest contacting us with specifics as early as possible for the best outcomes.

Sustainability is at the core of our operations. We utilize energy-efficient technologies, recycle scrap material, and follow strict environmental protocols to minimize our ecological footprint. Our commitment extends beyond compliance, aiming for a future-focused, sustainable approach in all we do.

Worker safety is paramount. Our factory complies with all health and safety regulations, providing regular training, enforcing strict on-site protocols, and equipping our staff with advanced safety gear. We believe a safe worker is an empowered worker.

Certainly. We pride ourselves on our capability to provide tailored solutions. Our team of experts collaborates closely with clients to understand their needs, offering custom compositions, cuts, and finishes unique to their project demands.

We manage logistics through trusted partners, ensuring timely and safe deliveries. Customers receive tracking information once orders are dispatched and can monitor their shipment in real-time. Additionally, our customer service team is always on standby to assist.

We stand by the quality of our products. In the rare instance of defects or non-compliance, we have a transparent return or exchange policy. Clients are encouraged to reach out within a specified period after receipt, and we promise a swift, fair resolution in line with our terms and conditions.

To become a model enterprise of integrity in the global steel industry, adhering to the concept of "Casting steel soul with sincerity, believing in great cause", running through every link of steel with the purest integrity.