If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

![]() Whatsapp : +8613589078962

Whatsapp : +8613589078962

![]() Email : [email protected]

Email : [email protected]

| item | Stainless Steel Plate/Sheet |

|---|---|

| Standard | GB |

| Length | 1000-6000mm |

| Thickness | 0.15-100mm |

| Width | 600-2500mm |

| Type | Plate |

| Application | Construction |

| Tolerance | ±1% |

| Processing Service | Bending, Welding, Decoiling, Punching, Cutting |

| Steel Grade | 301L, S30815, 301, 304N, 310S, S32305, 410, 204C3, 316Ti, 316L, 441, 316, L4, 420J1, 321, 410S, 410L, 436L, 443, LH, L1, S32304, 314, 347, 430, 309S, 304, 439, 204C2, 425M, 409L, 420J2, 436, 445, 304L, 405, 370, S32101, 904L, 444, 301LN, 305, 429, 304J1, 317L |

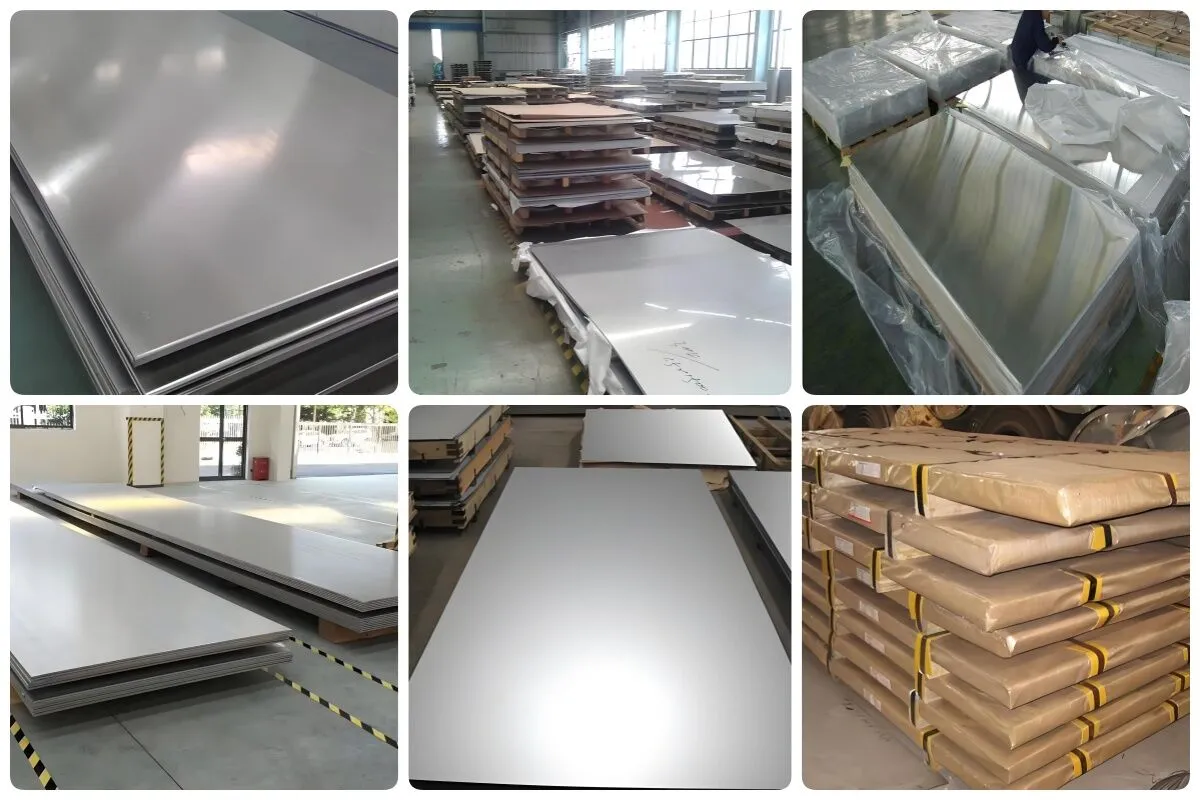

| Surface Finish | TSHS |

| Delivery Time | 8-14 days |

| Product name | 304 Stainless Steel Plate |

| Technique | Cold Rolled Hot Rolled |

| Surface | BA/2B/NO.1/NO.3/NO.4/8K/HL/2D/1D |

| Certification | ISO 9001 |

| MOQ | 1 Ton |

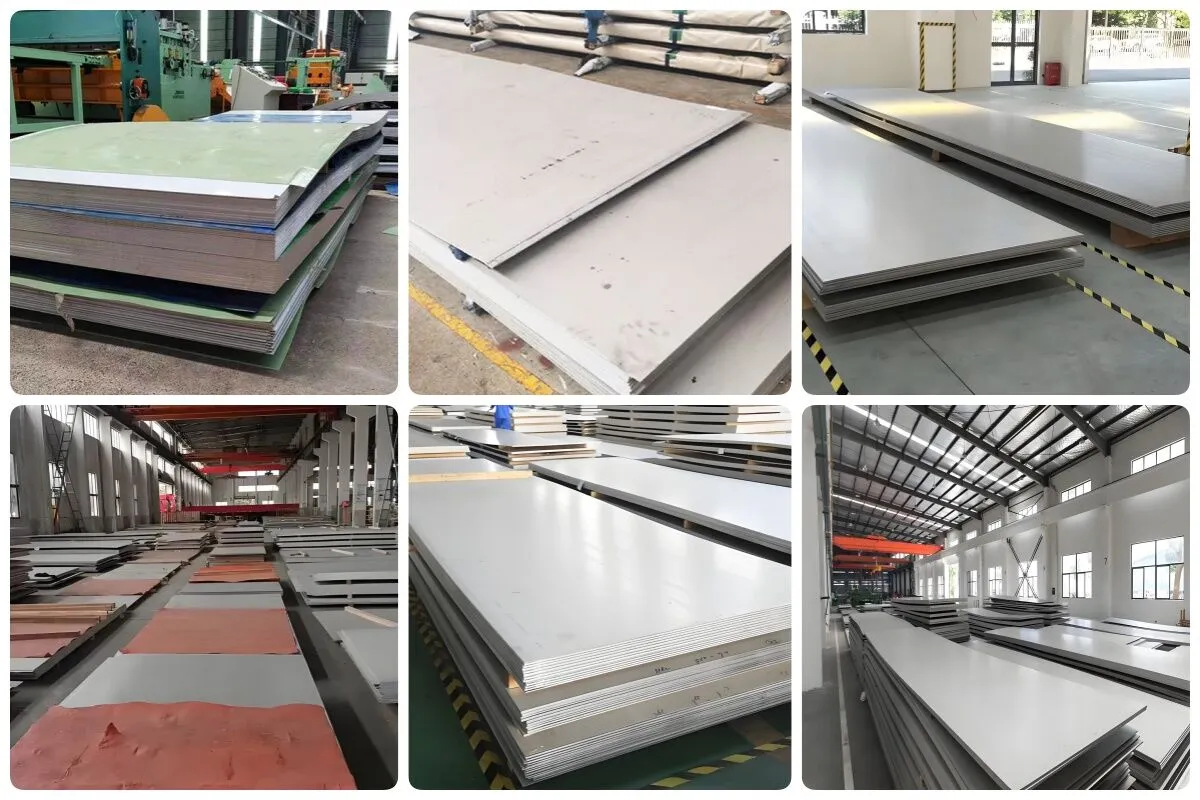

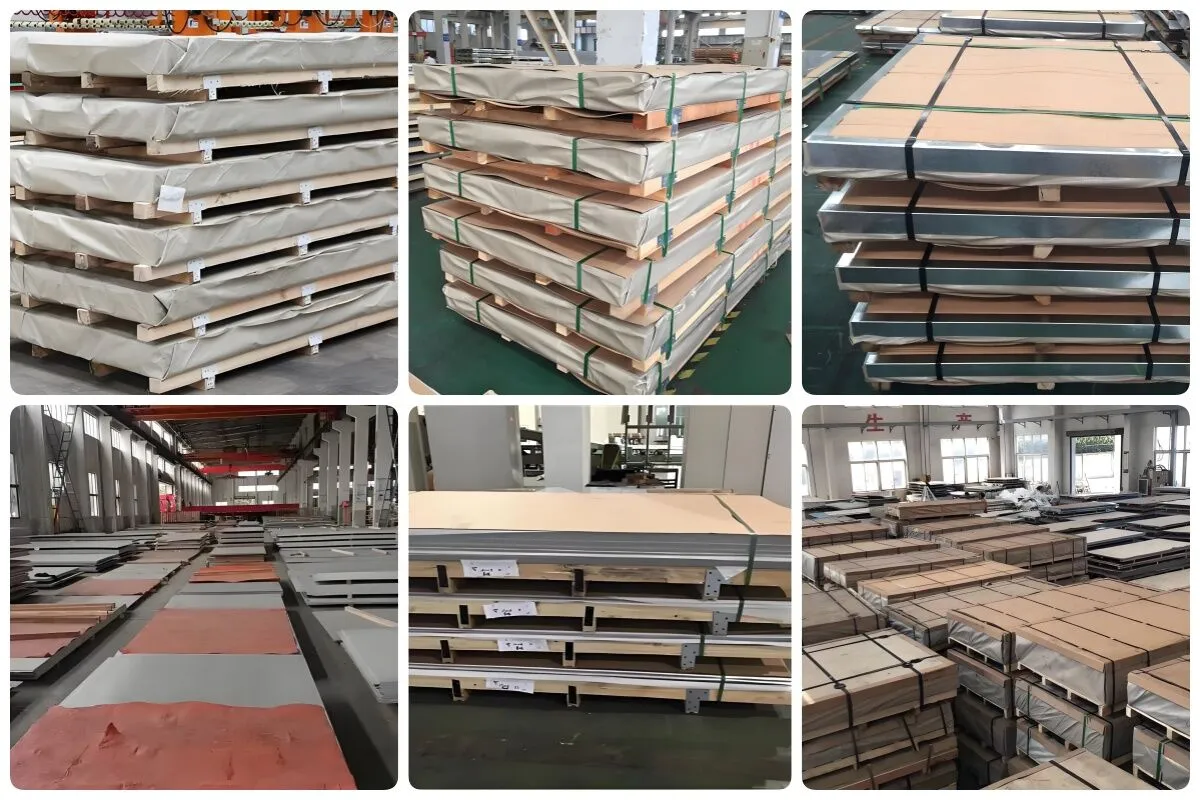

| Packaging | Standard Sea-worthy Packaging |

| Keyword | 304 304l Stainless Steel Plate |

| Shape | Flat.sheet |

| Material | 201/202/309/309S/310/310S/304/304L/316/316L/316Ti/321 |

| Price Term | CIF CFR FOB EX-WORK |

It is generally around 7.7 to 8.0 grams per cubic centimeter, with differences in different models. It is used for mass and volume related calculations.

The range is roughly 16-27 watts/(m · Kelvin), and the heat transfer capacity is limited, which has different effects on the heating of kitchen utensils and industrial heat dissipation. – ** Coefficient of thermal expansion **: about 10-20 × 10/Kelvin, will change in size due to temperature changes, be careful in the installation project.

Some stainless steels are magnetic, while others are non-magnetic or weakly magnetic, making them suitable for specific electronic or magnetic applications.

It has electrical conductivity, but it is inferior to metals such as copper. This property should be considered in some situations where electrical conductivity is required.

Stainless steel plate has high hardness, and different types and processing methods will make its hardness different. It can withstand certain friction and pressure, and can be used to make wear-resistant parts. – ** Gloss **: The surface has a metallic luster, and the gloss effect is different after different surface treatments (such as mirror, wire drawing). It is used for decoration to enhance aesthetics.

It has a certain degree of ductility and can be made into various shapes by stretching, bending, and other processing methods, such as curved panels for architectural decoration.

Corrosion resistance: containing alloying elements such as chromium, chromium can form a dense oxide film, preventing corrosive media such as oxygen and moisture from contacting metal substrates, resisting atmospheric corrosion, water corrosion, and chemical medium corrosion, such as in chemical and marine environments.

In high-temperature environments, stainless steel plates can also maintain good oxidation resistance because their alloy composition can form a stable oxide film on the surface, preventing further oxidation, which is valuable in high-temperature industrial equipment.

Under the action of many chemical substances (e.g. acids, bases, salt solutions), it can maintain a relatively stable chemical state, especially in food processing and medical equipment manufacturing, without harmful chemical reactions with food ingredients or medical disinfectants.

1. External wall decoration, stainless steel plate corrosion resistance, beautiful, used for modern building exterior walls. Has a variety of surface effects, can reflect the environment, anti-corrosion, reduce maintenance costs.

2. Interior decoration, used for elevator car siding, strong and durable, can improve the decorative effect through process. Also used for indoor partition, beautiful and easy to clean, suitable for a variety of places.

3. Roofing material, good waterproof performance, high strength, can be used in industrial buildings or building roofs with high waterproof requirements, can withstand wind and snow, long service life.

1. Chemical equipment manufacturing, resistant to chemical substances, used in the manufacture of reaction kettles, storage tanks, etc., but also to help heat exchange, to ensure chemical production.

2. Food processing equipment, in line with food hygiene standards, easy to clean and disinfect, smooth surface, used in the production of food processing equipment to ensure food quality.

3. Automobile manufacturing

used for automotive exhaust system components to withstand high temperature and exhaust gas corrosion, and also used for some appearance decorative parts to enhance texture.

1. It is used to make pots and tableware, with good thermal conductivity, durability, easy cleaning, and meets the needs of use.

2. Household goods

It is used for furniture frames and decorative components to add a sense of style and sturdiness, and is also used for home decorations.

3. Medical equipment

It is used in the manufacture of surgical instruments and medical equipment casings to meet the requirements of instrument hardness, corrosion resistance, and easy sterilization, and to improve the quality of equipment.

It has been selected as one of the top 500 Chinese enterprises for 14 consecutive years, with strong financial and technical strength.

Process efficiencyDRP information is fully integrated and controlled, and the steel production process is at a high level.

A steel enterprise that takes steel production as its leading industry and integrates commercial, high-tech and other industries.

Created a number of "firsts" in China's steel industry, with strong R & D capabilities and technological innovation capabilities

The products cover products, varieties, and specifications, and can meet the diverse needs of customers in different fields.

Products with high quality quickly occupied the domestic market and were successfully exported to many countries and regions.

Our factory manufactures a comprehensive array of steel products, including but not limited to, structural beams, steel bars, plates, and coils. We also offer bespoke solutions catering to specific dimensions and compositions as per customer requirements.

Absolutely, all our steel products adhere to international standards and undergo rigorous quality assurance tests. We hold various certifications, including ISO 9001, emphasizing our commitment to quality. Each product batch comes with a certification detailing its grade and compliance standards.

Yes, we are equipped to manage significant order volumes even within constrained timelines, thanks to our advanced operational processes, sizable workforce, and efficient logistics network. However, we always suggest contacting us with specifics as early as possible for the best outcomes.

Sustainability is at the core of our operations. We utilize energy-efficient technologies, recycle scrap material, and follow strict environmental protocols to minimize our ecological footprint. Our commitment extends beyond compliance, aiming for a future-focused, sustainable approach in all we do.

Worker safety is paramount. Our factory complies with all health and safety regulations, providing regular training, enforcing strict on-site protocols, and equipping our staff with advanced safety gear. We believe a safe worker is an empowered worker.

Certainly. We pride ourselves on our capability to provide tailored solutions. Our team of experts collaborates closely with clients to understand their needs, offering custom compositions, cuts, and finishes unique to their project demands.

We manage logistics through trusted partners, ensuring timely and safe deliveries. Customers receive tracking information once orders are dispatched and can monitor their shipment in real-time. Additionally, our customer service team is always on standby to assist.

We stand by the quality of our products. In the rare instance of defects or non-compliance, we have a transparent return or exchange policy. Clients are encouraged to reach out within a specified period after receipt, and we promise a swift, fair resolution in line with our terms and conditions.

To become a model enterprise of integrity in the global steel industry, adhering to the concept of "Casting steel soul with sincerity, believing in great cause", running through every link of steel with the purest integrity.